High Density Fiberboard (HDF) vs Medium Density Fiberboard (MDF)

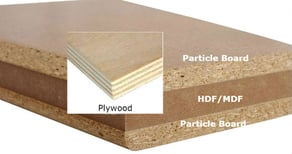

MDF (Medium Density Fiberboard) and HDF (High Density Fiberboard) are two types of fiberboard, which are engineered wood products made from wood fibers and resin binders.

Both MDF and HDF are denser and more stable than particleboard, and they are often used as a substitute for solid wood in the construction of furniture, cabinetry, and other wood products.

Definition of Fiberboard - What is Fiberboard?

Fiberboard is a strong and versatile material that is commonly used in many facets of construction. It consists of wood fiber or flour pressed together under heat, with an adhesive binder.

The fiberboard can come in various thicknesses and densities, depending on the application.

It can be sanded and painted as necessary, making fiberboard well-suited for flooring, cabinetry, wall panels, furniture pieces, ceiling tiles and more.

With its high strength levels, fiberboard provides a cost effective solution while allowing manufacturers to maintain a level of quality assurance.

Fiberboard is a type of engineered wood product composed of cellulose fibers, usually adhered together with a synthetic resin or binder.

It is not as strong as solid wood, however fiberboard is lighter and can be more easily cut and drilled.

It is mostly used in furniture, doors and acoustic insulation due to its ability to provide a lightweight, economical material with good acoustical performance.

Different fiberboards come with various pros and cons; for instance fiberboard panels generally produce high levels of sound-dampening properties but are not waterproof so manufacturers must add coatings to achieve that effect.

Overall, fiberboard has become an indispensable part of the construction industry due to its flexibility and durability in any number of projects.

What is High Density Fiberboard (HDF)?

High Density Fiberboard (HDF) is a high-quality composite material that is thinner and denser than regular particle board.

It is composed of wood fibers which are compressed and bonded together with resin under high pressure and high heat, creating an incredibly strong material.

HDF offers numerous advantages, such as high resistance to wear and tear, high resistance to warping or splitting due to changes in humidity and temperature, a smooth finish which can be used in flooring applications or painted as desired, high moisture resistance along with good compressive strength meaning it can withstand loads transmitted from above or below.

This makes HDF an ideal choice for furniture or cabinets, where weight capacity is important or high traffic areas where flooring needs to be extremely durable.

What is Medium Density Fiberboard (HDF)?

Medium Density Fiberboard (MDF) is a type of manufactured wood created through the process of breaking down hardwood or softwood residuals into small fibers.

These fibers are then combined with wax and resin and pressed into flat surface boards. MDF is well-known for its high strength, low cost, and resistance to shrinking and warping due to its composite nature. %20vs%20Medium%20Density%20Fiberboard%20(MDF).jpg?width=371&height=193&name=High%20Density%20Fiberboard%20(HDF)%20vs%20Medium%20Density%20Fiberboard%20(MDF).jpg)

Because of this, it is often used in furniture manufacturing in place of traditional wooden boards.

Additionally, MDF doesn't require any veneer or laminate finish due to its smooth surface; however, because it lacks internal grain like other forms of wood, it is more susceptible to impact damage.

Despite this minor drawback, MDF remains a versatile and popular building material used by many industries around the world.

Benefits of Using High Density Fiberboard (HDF) & Medium Density Fiberboard (MDF)

High density fiberboard (HDF) and medium density fiberboard (MDF) are two essential building materials used in various construction projects.

HDF is widely used for flooring, doors, and paneling applications due to its ability to resist rot, mold, and moisture from its laminated fiber structure.

MDF can be ideal for worktops and furniture because it is lighter than HDF and can be easily cut with a saw or router.

Both fiberboards offer immense benefits in many aspects such as cost-effectiveness and ease of use while offering the same quality level of workmanship.

With sustainability increasingly being a priority in construction today, fiberboards are becoming more popular due to their non-toxic nature, which makes them safe for everyone involved in these projects.

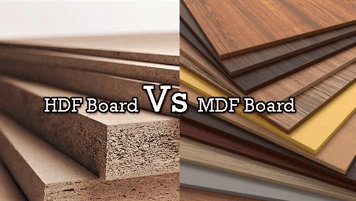

Comparison between High Density Fiberboard (HDF) and Medium Density Fiberboard (MDF)

One of the main differences between MDF and HDF is the density of the board. MDF has a lower density than HDF, which means that it is not as strong or durable.

MDF is more prone to warping, splitting, and cracking, and it is not suitable for use in structural applications.

HDF, on the other hand, is much denser and more stable, and it is often used in applications where high strength and durability are required.

Another difference between MDF and HDF is the way they are manufactured.

MDF is made by breaking down hardwood or softwood fibers into small particles, which are then mixed with resin and other additives to form a dough-like material.

This material is then pressed into sheets using high temperature and pressure, resulting in a smooth, uniform surface with no visible wood grain.

HDF, on the other hand, is made from fibers that are broken down into even smaller particles and mixed with a higher proportion of resin. This results in a denser, harder board with a smoother surface and less visible wood grain.

Overall, MDF is a less expensive and less durable alternative to HDF, and it is typically used in applications where strength and durability are not critical.

HDF is more expensive and more durable, and it is often used in applications where high strength and durability are required.

How is High Density Fiberboard (HDF) Used?

HDF (High Density Fiberboard) is a versatile, cost-effective material that is used for a variety of applications.

HDF can be used in furniture construction and cabinetry, as it provides better resistance to changes in humidity and offers more strength than traditional particle board.

It has also been used in the production of doors and windows due to its smooth edges, rigidity, and dent resistance.

HDF can even be found as flooring such as laminate or engineered hardwood floors as it provides extra durability compared to solid wood.

HDF is an increasingly popular choice for its affordability, versatility, and sturdiness.

How is Medium Density Fiberboard (MDF) Used?

MDF, or Medium Density Fiberboard, is a widely used composite material made up of wood fiber and resin that is extremely versatile.

MDF can be found in many mass-produced items such as cabinet doors, furniture, shelving units, home decor products, architectural molding and more.

MDF is considered to be one of the most affordable materials when it comes to building due to its easy machinability and low cost.

MDF is also popular for storage boxes because it does not easily dent or scratch like other materials.

MDF has also been increasingly used for art projects due to its smooth surface finish and ability to accept glue efficiently.

MDF’s versatility makes it suitable for numerous applications in both home projects as well as larger commercial designs.

Popular Applications for High Density Fiberboard (HDF) & Medium Density Fiberboard (MDF)

Popular Applications for High Density Fiberboard (HDF) & Medium Density Fiberboard (MDF)

High Density Fiberboard, or HDF, is an incredibly versatile material that has been used in construction and manufacturing for years.

HDF is known for its durability and strength, making it popular for a variety of industries.

HDF is often seen in furniture, cabinets, doors, molding and flooring applications due to its durability and ability to be cut and molded into intricate shapes without losing its structural integrity.

HDF is also frequently used as a substrate layer in the production of decorative laminates like those found on countertops and high-end appliances.

Aside from these, HDF has also become increasingly popular among carpenters employed in the construction industry due to its longevity and resistance to rot.

HDF continues to become more popular with every passing day due to its increased affordability and ease of use.

Popular Applications for Medium Density Fiberboard (MDF)

MDF, or Medium Density Fiberboard, is an engineered wood panel product made from wood fibers glued under heat and pressure.

MDF has several advantages over other types of wood-based products, including uniformity of size and strength, ease of cutting and handling, and cost savings.

MDF is now commonly used in construction projects due to these advantages. .jpg?width=260&height=193&name=images%20(1).jpg)

MDF can be used to construct cabinetry and furniture, since it can be painted or laminated to produce a range of colors and textures.

It is also used as internal wall padding in homes as well as acoustic insulation for studios and other sound-sensitive areas.

MDF has greater structural integrity than particleboard but is lighter in weight than plywood, making it suitable for many different applications such as shelving units or even entertainment centers.

MDF's versatility makes it one of the most popular materials across a variety of industries.

Advantages and Disadvantages of High Density Fiberboard (HDF) & Medium Density Fiberboard (MDF)in Specific Applications

High-Density Fiberboard (HDF) and Medium-Density Fiberboard (MDF) are popular building materials used in cabinet doors, countertops, flooring, shelves, moldings and many other home furnishings.

Thanks to their durability and relative affordability, they have become staples in the construction industry.

Each also has distinct advantages and disadvantages that can affect specific applications.

HDF is more durable than MDF, making it stronger and less likely to expand or contract under different temperatures.

It also stands up better against moisture without suffering degradation or long-term warping issues.

However, HDF is denser than MDF making it heavier and more expensive.

That said, the price of each material depends on the level of quality desired for a particular job.

On the other hand, MDF is lighter than HDF but not as durable or resistant to moisture damage as a result.

Additionally, MDF does contain formaldehyde which can be toxic when exposed to certain environments for an extended period of time - an important consideration for people with allergies or respiratory issues.

No matter which material one chooses for their project, both HDF and MDF offer unique advantages depending on the application they are being used in.

Cost Comparison of High Density Fiberboard (HDF) & Medium Density Fiberboard (MDF)

When looking at the cost of HDF and MDF, it's important to look beyond just the board itself.

In addition to the type of wood and finish, you also need to consider how much labor is required for installation.

Generally speaking, HDF is more expensive due to its increased density.

However, this additional cost is often offset by the fewer hours necessary for installation - as in a few cases they can be laid directly over existing flooring surface with no extra preparation work - allowing projects to be completed quickly and with less labor involved.

On the other hand, MDF will require additional preparation time before laying, increasing labor costs significantly.

Ultimately the choice between HDF and MDF comes down to what makes most sense financially based on your project goals and timeline.

Making the Final Decision Between High Density Fiberboard (HDF) & Medium Density Fiberboard (MDF)

In conclusion, both HDF and MDF offer unique advantages for a variety of applications depending on the level of strength and durability needed.

However, when it comes to cost, HDF is typically more expensive than MDF due to its increased density and number of labor hours required for installation.

Ultimately what matters most is that you select the material that is best suited to your needs and budget.

By understanding the advantages and disadvantages of both HDF and MDF, you can make an informed decision that ensures your project will be completed on time and within budget.

All Your Flooring, Cabinet, and Countertop Needs in ONE Place!

We carry white speckled quartz, White shaker cabinets near me", kitchens with vinyl plank flooring, wholesale cabinet warehouses near me, wholesale cabinets and floors, Laminate flooring, vinyl flooring, white shake pantry, vanities for remodel, vanities for bathrooms, white vanities for the kitchen, wood colored vinyl flooring, white countertops, marbled countertops, vinyl flooring for a remodel, white shaker vanity cabinets, speckled quartz countertops for kitchens, wholesale cabinets in Seattle, wholesale flooring in Seattle, vinyl flooring store near me, vinyl flooring store in Seattle, vinyl flooring store, white shaker cabinets available in Seattle now, shaker cabinets near me, laminate flooring near me, vinyl flooring near me, natural wood colored flooring for sale near Seattle, Kitchen Cabinet warehouse, Kitchen Cabinet Store, Cabinets near me, Luxury Vinyl Plank, LVP Flooring, Luxury Vinyl Plank Flooring, RTA Cabinets, Prime Windows, Window Store ,Window Storefront, Glass Windows, Glass Windows near me, Window manufacturer, window manufacturer near me, replacement windows Seattle, In Stock Windows near me, new windows near me, windows depot near me, doors and windows Seattle, Windows Shop, Windows Shop near me, RTA Cabinetry, Ready to Assemble Cabinets, Luxury Vinyl Plank store, flooring store, cabinet warehouse, natural wood colored vinyl flooring planks, waterproof laminate flooring near me, vinyl flooring planks near me, laminate flooring planks near me, Vinyl flooring planks near Seattle, white kitchen cabinets, white bathroom cabinets, white shaker kitchen cabinets, white bathroom vanity with cabinets, white bathroom vanity with drawer, white cabinet bathroom vanity with drawers, vinyl flooring that looks like wood, laminate floor that looks like wood, laminate flooring like wood in Seattle, vinyl flooring like wood in Seattle, vinyl flooring that looks like wood in Seattle, wholesale Flooring planks near me, Vinyl flooring planks near Seattle, vinyl plank flooring, cabinet warehouse near me, wholesale cabinet warehouse, wholesale flooring warehouse, countertop warehouse, cabinet warehouse, flooring warehouse, luxury vinyl plank flooring near me, vinyl plank flooring near me, bathroom vanity near me, laminate flooring on sale, laminate flooring on discount, Kitchen Designer, Online Kitchen Cabinet Designer, Kitchen Designer near me, Online Kitchen Designer, Online Kitchen Design Service, vinyl flooring sale, vinyl flooring on sale, vinyl flooring on sale in Seattle now, wholesale vinyl flooring on sale in Seattle now, white vanities on sale near me, white vanities on sale now in Seattle, white vanities with drawers on sale, Vinyl Flooring Planks for Sale, Cabinets For Sale, Countertops for sale, white vanities without drawers, white vanities with drawers and cupboard, & more!